Contracts for Iter components awarded

04 October 2012

More contracts have been awarded for components to be used in the next generation fusion reactor, Iter, being built in France. Indian, Russian and US companies will supply components and services for the experimental reactor.

|

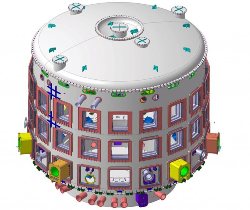

L&T will produce the enormous cryostat

(Image: Iter) |

India's Larson & Toubro (L&T) has been awarded a contract to supply the massive cryostat that will form the vacuum-tight container surrounding the Iter vacuum vessel and the superconducting magnets. The cryostat - measuring almost 30 metres in diametre and 29 metres in height and weighing a colossal 3800 tonnes - will "essentially act as a very large refrigerator," the Iter Organization said. It will be made of stainless steel with a thickness ranging from 50mm to 250mm. It will be the largest vacuum vessel ever made of stainless steel.

The cryostat will have several penetrations allowing internal access for maintenance, as well as over 200 penetrations - up to four metres in size - providing access to the vacuum vessel for cooling systems, magnet feeders, auxiliary heating, diagnostics, and the removal of blanket and parts of the diverter. Large bellows will be located between the cryostat and the vacuum vessel to allow for thermal contraction and expansion in the structures.

A contract for the manufacture of the cryostat was signed on 17 August by project director of Iter-India Shishir Deshpande and the vice president of L&T's heavy engineering division, Anil Parab. Under the contract, L&T will manufacture the massive component at its Hazira plant near Surat in Gujarat state. It will be shipped to the Iter site in Cadarache, southern France, in 54 modules. These modules will then be pre-assembled in a temporary workshop on the site before being transported to the tokamak pit where they will be welded together.

Iter director general Osamu Motojima commented, "The cryostat is an essential part of the Iter machine. Seeing this huge component taking shape in the factory is certainly important and encouraging news. It means that the Iter project has entered a decisive phase."

Russian conductors

Meanwhile, Russia is to supply conductors for use in the magnetic system of the Iter reactor. It is to produce 22km of wires for the windings of the toroidal field coils, which will use more than 90 tonnes of niobium-tin (Nb3Sn) superconducting strands and 11km of wires for the windings of the poloidal magnetic field coils using some 40 tonnes of niobium-titanium (NbTi) superconducting strands.

So far, work on ten of the eleven contracts for the manufacture and supply of wire components for the Iter project is already in progress, with some of these in the final qualification phase.

At a recent meeting in Moscow, Iter's head of superconductors Arnault DeVries noted that work on the production of conductors for the Iter project was going to schedule. He said, "Despite the difficulties associated with the need to coordinate the work of more than 30 vendors and six national Iter agencies responsible for the production of conductors, our community has always been able to work in close cooperation, and similar meetings have always been a great opportunity to share experiences and to address urgent issues."

Putting it all together

US-based engineering and geospatial software provider Intergraph is to supply a suite of products to handle the assembly, commissioning and construction of the Iter reactor at Cadarache.

Under an agreement with Iter, Intergraph will implement some of its SmartPlant Enterprise solutions, such as SmartPlant Foundation, SmartPlant Construction, SmartPlant Materials and SmartPlant Enterprise for Owner Operators. During the plant design, construction and commissioning, SmartPlant Enterprise for Owner Operators will provide preconfigured processes to support engineering and project execution work processes, while SmartPlant Foundation will play a key role in data synchronization and data sharing. Intergraph's SmartPlant Enterprise software will also help to create synchronized information and centralized data, offering improved management of work processes, control equipment and maintenance, coordination of contractors and management of change.

The Iter project - a collaboration between the European Union, Russia, India, China, Japan, Korea and the USA - aims to demonstrate that it is possible to produce energy from fusion. The project relies upon in-kind contributions from these member countries for component work packages which have been divided between them. The first equipment for the Iter reactor is due to be delivered to the Cadarache site from 2014. The tokamak assembly is scheduled to arrive in 2015. Construction is set to be complete in 2019, with the first operation of the reactor expected to take place in 2020.

Researched and written

by World Nuclear News