Making space at Sellafield

31 July 2013

New cutting and decontamination methods are being trialled to clear away old equipment more quickly and free space to store higher priority wastes at Sellafield.

|

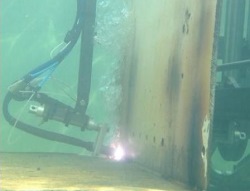

| A plasma arc cutter in action during research (Image: Sellafield Ltd) |

If demonstrated, the technique could be used to cut up hundreds of old skips that were used to hold used nuclear fuel rods from Magnox reactors in Sellafield's Fuel Handling Plant. If the skips can be reduced in size then the space they take up can be used for a much higher priority decommissioning project - the clean-up of the 60-year old First Generation Magnox Storage Pond (FGMSP).

Head of FGMSP Martin Leafe said that completing the disposal route for the skips is vital to the plan to start retrieving legacy fuel from the pond in 2015.

A trial skip was cut up at Sellafield using an underwater plasma arc and the pieces were then taken to Magnox Ltd's decommissioning centre at Hinkley Point A. There the metal parts are to be stripped of paint and milled to remove sub-surface contamination. Leafe said that collaborating with Magnox Ltd in this way could save "potentially millions of pounds of taxpayers' money." Ultimately, some 2000 skips are to be disposed of and this will be cheaper if they can be effectively decontaminated and reduced in size. The plasma arc method was selected after experiments with fibre lasers and diamond wire.

Cleaning up the FGMSP is one of the highest priorities in UK nuclear decommissioning due to the corrosion suffered by the fuel over time and the resulting highly radioactive sludge. Tackling this has involved a long-running and innovative program of remote underwater surveys and development of new techniques to handle and store the sludge safely.

It is the Nuclear Decommissioning Authority that manages the assets and facilities from the UK's former national research and nuclear power program. The work is funded partly by government and partly by income from those NDA facilities that remain in commercial operation - including one Magnox reactor at Wylfa and the Thorp reprocessing plant.

Researched and written

by World Nuclear News