Shadow corrosion creates 'images' of nearby parts on the surface of zirconium alloy (zircaloy) fuel rods and fuel channels, with a thicker layer of zirconium oxide, likened to rust on steel, and can create pinholes in the zircaloy cladding around fuel rods.

No meltdowns have been caused by it, but it does mean that fuel rods need to be replaced earlier than planned.

Gary Was, professor emeritus of nuclear engineering and radiological sciences at the university, and author of the study published in the Journal of Nuclear Materials, says "it can also warp the channels between fuel assemblies, potentially preventing control blades regulating the reactor power".

"The advantages of longer fuel life and a reduced risk of fuel failure include lower fuel cost, fewer outages, less radiation exposure for workers and lower maintenance cost, all of which lower the operating cost for the reactor," Was said.

What equipment did the researchers use?

The researchers used a high-temperature, high-pressure water cell recreating the environment of a reactor core in the Michigan Ion Beam Laboratory to successfully reproduce shadow corrosion outside of a reactor for the first time.

Lead researcher Peng Wang, assistant research scientist in nuclear engineering and radiological sciences at U-M, called it a "very unique set-up".

Ion beams can test nuclear materials 1000 times faster, and at 1000th of the cost, compared with research reactors. They accelerate the aging of nuclear materials because they produce more intense radiation.

"Until now, shadow corrosion was never reproduced in laboratory autoclave experiments because the simultaneous effect of irradiation was needed. What the University of Michigan experiment has shown was the simulation of the actual plant situation," said Raul Rebak, a corrosion engineer at GE Research, part of GE, which was not involved with the research but is the world’s leading manufacturer of boiling water reactors.

How University of Michigan explains the research process

Contact between zircaloy fuel rods and the nickel alloy of the supporting structure creates a voltage that drives the corrosion reaction. But completing the circuit requires radiation to split water molecules, producing more reactive entities such as hydrogen peroxide. These form at the nickel alloy surface and then diffuse to the zircaloy surface, accelerating its corrosion.

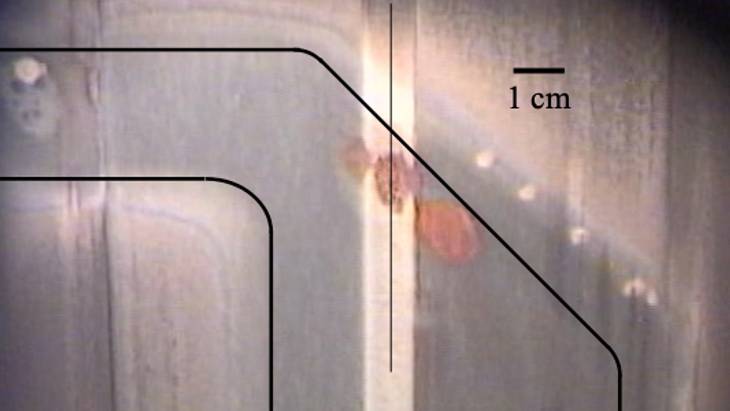

Wang demonstrated this with a flat nickel alloy sample running parallel to the zircaloy sample in the corrosion cell and with a curved sample that varied in its distance from the zircaloy. The curved sample showed that the zircaloy was more heavily oxidised where it was closer to the nickel alloy, the level of oxidation decreasing with distance.

What about a solution?

Wang and Was’s work was funded by the French company Framatome and their collaboration hopes to be able to announce proposed solutions to shadow corrosion in the next year.

"This result highlights the versatility and the high degree of control that accelerators and ions offer to create experiments with very well-controlled conditions that mimic the reactor environment," Was said.

"You can study problems to the point where you understand the processes and then develop solutions."

_28178.jpg)

_66891.jpg)

_55296.jpg)

_16128_62584.jpg)