According to TVEL, which is Rosatom's fuel division, the new machine "surpasses all centrifuges of previous generations operating at Rosatom enterprises".

It said the new generation centrifuges would undergo pilot industrial operation at one of TVEL's sites, adding that "testing in the uranium enrichment shop will be the final stage of development, which precedes the introduction" of the machines "to serial production".

Alexander Ugryumov, Senior Vice President for Scientific and Technical Activities of TVEL JSC, called the development "a historic achievement by our designers, technologists and manufacturers".

He added: "We are continuing the programme of modernisation of our enrichment capacities with a phased replacement of old-generation centrifuges with modern and highly efficient GC-9+ machines, which will operate for decades. The GC-10 is another step forward, which in the future will help make our separation plants even more modern and efficient."

Gas centrifuges use centrifugal force to separate the lighter isotopes of uranium-235 from the heavier isotopes of uranium-238. TVEL's report on the tenth generation machine does not specify the difference with the ninth and 9+ machines, but says "the difference between generations of Russian gas centrifuges is the growth of their efficiency and productivity".

Background

Unenriched, or natural, uranium contains about 0.7% of the fissile uranium-235 (U-235) isotope. ("Fissile" means it's capable of undergoing the fission process by which energy is produced in a nuclear reactor). The rest is the non-fissile uranium-238 isotope. Most nuclear reactors need fuel containing between 3.5% and 5% U-235. This is also known as low-enriched uranium, or LEU. Advanced reactor designs that are now being developed - and many small modular reactors - will require higher enrichments still.

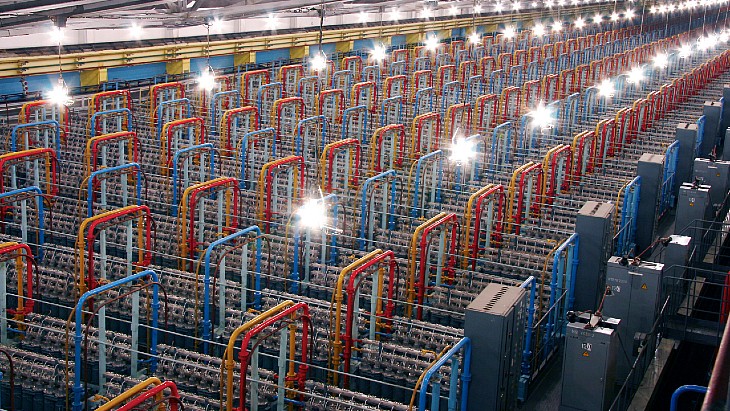

Enrichment increases the concentration of the fissile isotope by passing the gaseous uranium hexafluoride through gas centrifuges, in which a fast spinning rotor (a thousand revolutions per second) inside a vacuum casing makes use of the very slight difference in mass between the fissile and non-fissile isotopes to separate them. As the rotor spins, the concentration of molecules containing heavier, non-fissile, isotopes near the outer wall of the cylinder increases, with a corresponding increase in the concentration of molecules containing the lighter U-235 isotope towards the centre. World Nuclear Association’s information paper on uranium enrichment contains more details about the enrichment process and technology.

_33198.jpg)

_730_93825.jpg)

_83147.jpg)