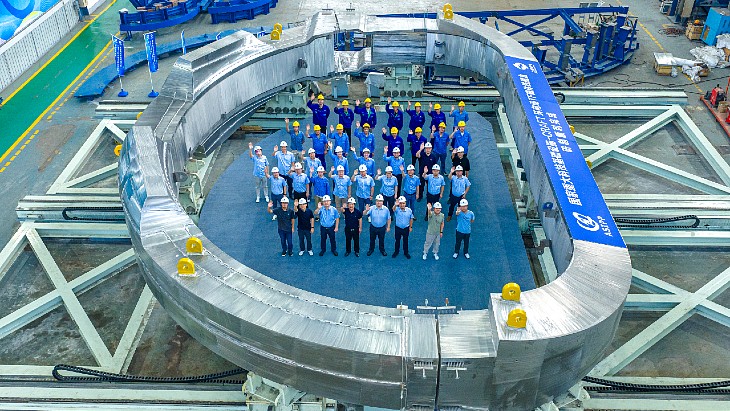

Shanghai Electric delivered the coil box, the primary load-bearing structural component of the toroidal field magnet and a core component of the magnet system as it protects the toroidal field coil windings and supports and secures other superconducting magnets, including the poloidal field magnet.

Consisting of ultra-low-temperature austenitic steel, it weighs 400 tonnes and Shanghai Electric said it was the world's largest toroidal field magnet coil box, at more than 1.2-times the size, and about twice the weight, of similar components in the multinational ITER fusion project in France.

The project team spent five years overcoming numerous technical challenges, said the Institutes of Physical Science, Chinese Academy of Sciences, adding: "In terms of manufacturing technology, facing the challenge of welding with a maximum thickness of 360mm, they developed a combination of high-thickness laser welding and ultra-deep narrow-gap tungsten inert gas welding, as well as phased array non-destructive testing technology, achieving shape and quality control during coil box welding. They also developed precision forming technology for 30-metre-long space bends and cooling tube fixation using low-temperature resin and brazing, enabling high-precision installation of the cooling tubes."

"The successful delivery of the coil box not only accumulates relevant technical experience for the manufacturing of high-end equipment for China's fusion devices, but also fosters a comprehensive, end-to-end industrial supply chain system, marking a significant step towards the commercialisation of fusion energy. The related technologies can also be applied in aerospace, energy equipment, shipbuilding, and offshore engineering."

Shanghai Electric said that the work "demonstrates its outstanding innovation and high-end manufacturing capabilities in major projects".

The company, in collaboration with the Institute of Plasma Physics, in July completed the design and delivery of the magnet cold test cryostat for the International Thermonuclear Experimental Reactor (ITER). The item, the largest transported, arrived at the construction site in Cadarache, southern France, following a 104-kilometre-long journey by road from the port of Berre-l'Étang, near Marseille.

_71653.jpg)

The giant delivery to ITER (Image: ITER organisation)

The cryostat - into which some of the D-shaped toroidal field coils as well as PF1, the smallest of the ring-shaped poloidal field coils, will be inserted - is shaped "like a giant sardine box", the ITER Organisation said. It measures 22 metres in length and almost 11 metres in width and weighs 330 tonnes.

Shanghai Electric said that with its two decades of experience in the "future-oriented energy technology" of fusion, "industrialisation is key to driving technological breakthroughs and commercial applications".

Background

According to the recently published IAEA World Fusion Outlook 2025: "The Institute of Plasma Physics at the Chinese Academy of Sciences is advancing a complementary suite of facilities that together address physics, engineering and fuel cycle questions that will be foundational for future fusion plants."

These include the Comprehensive Research Facility for Fusion Technology (CRAFT), "now in the final stages of construction ... designed as a single campus-style platform bringing together some 20 specialised test stands covering superconducting magnets, heating and current-drive systems, blankets, and tritium technologies.

"Its purpose is to help address the engineering integration challenges involved in advancing magnetic fusion energy from present experiments towards a functional fusion power plant.

"The BEST tokamak is being built at the same site, next to the CRAFT facility, to explore steady state control of deuterium-tritium plasmas and to validate tritium production, extraction and recycling schemes. Civil works began in 2023, with a target of 2027 for first deuterium plasma; plans for subsequent deuterium-tritium operation are under review."

ITER is a major international project to build a tokamak fusion device designed to prove the feasibility of fusion as a large-scale and carbon-free source of energy. The goal of ITER is to operate at 500 MW (for at least 400 seconds continuously) with 50 MW of plasma heating power input. It appears that an additional 300 MWe of electricity input may be required in operation. No electricity will be generated at ITER.

Thirty-five nations are collaborating to build ITER - the European Union is contributing almost half of the cost of its construction, while the other six members (China, India, Japan, South Korea, Russia and the USA) are contributing equally to the rest. Construction began in 2010 and the original 2018 first plasma target date was put back to 2025 by the ITER council in 2016. However, in June last year, a revamped project plan was announced which aims for "a scientifically and technically robust initial phase of operations, including deuterium-deuterium fusion operation in 2035 followed by full magnetic energy and plasma current operation".

_730_93825.jpg)

_83147.jpg)

_87299.jpg)