Unit 5 of the Yangjiang nuclear power plant in China's Guangdong province has been connected to the electricity grid, China General Nuclear (CGN) announced yesterday. The unit - the first ACPR1000 reactor to be built and the first Chinese unit to feature a domestically-developed digital control system - is scheduled to enter commercial operation later this year.

.jpg) |

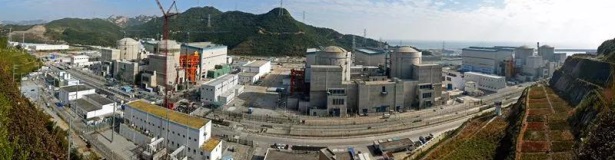

| The six-unit Yangjiang nuclear power plant (Image: CGN) |

CGN said the unit was connected to the grid at 9.12pm on 23 May. The milestone marks the formal transition of Yangjiang 5 from the construction and commissioning phase into the power generation phase. CGN noted that it is the first new Chinese nuclear power unit to be grid connected this year. Yangjiang 5 becomes its 21st operational power reactor.

"During the entire grid-connection process, the parameters of the unit's equipment were normal and stable, and the unit was in good condition," CGN said. "The unit has now entered the final load stage before commercial operation."

Six units are planned for the Yangjiang site. The first four units are CPR-1000s, with units 5 and 6 being ACPR-1000s. Unit 1 entered commercial operation in March 2015, with units 2, 3 and 4 following in June 2015, January 2016 and March 2017, respectively. First concrete for Yangjiang unit 5 was poured in September 2013, with that for unit 6 following three months later. All six reactors should be in operation by 2019.

Digital control system

CGN noted that Yangjiang 5 became the first operational reactor that features a digital control system designed in China.

"This is a landmark event in the field of China's nuclear power major technical equipment manufacturing," it said. "China has thus become the fourth country to master the technology after the USA, France and Japan."

The FirmSys digital instrumentation and control (I&C) system developed by CGN's Beijing CTEC System Engineering Co Ltd subsidiary. The company described the system as the "nerve centre" of a nuclear power plant, capable of controlling more than 260 plant systems running nearly 10,000 pieces of equipment and process conditions. It plays an important role in the safe, reliable and stable operation of nuclear power plants, it said.

According to CGN, FirmSys - launched in 2010 - has already been used in the upgrades of several of China's operating plants. However, Yangjiang 5 is the first new reactor to feature the system. CTEC and CGN signed a contract in 2013 for the supply of the FirmSys system for the unit. The I&C system was delivered in November 2016.

The system is also to be employed at Yangjiang 6, as well as units under construction at the plants including Hongyanhe, Tianwan and Fangchenggang, as well as the demonstration high-temperature gas-cooled reactor at Shidaowan. In July 2016, the International Atomic Energy Agency concluded that FirmSys meets IAEA Safety Standard requirements.

France's Framatome announced today that it provided the digital safety I&C system for unit 3 of China National Nuclear Corporation's Tianwan nuclear power plant in Jiangsu province. That unit - a Russian-supplied VER-1000 - was connected to the grid on 30 December 2017 and is scheduled to enter commercial operation later this year.

The announcement came as Framatome and the Russian company JSC Rusatom Automated Control Systems (JSC RASU) signed a memorandum of understanding (MoU) to enhance their cooperation in the field of I&C. The MoU was signed on the sidelines of the St Petersburg International Economic Forum.

The agreement notably provides a framework for the participation of RASU and Framatome in VVER and Framatome's nuclear power plant projects in the global market, cooperation in the fields of maintenance and modernisation, training, development of nuclear infrastructure, and support for the certification of Russian equipment to ensure compliance with European and international norms and standards. The parties will also look at how to integrate Framatome I&C systems into Rosatom new build projects abroad, with the possible localisation of component and system production on Rosatom sites.

Researched and written

by World Nuclear News

_91467.jpg)

_47120.jpg)

_16439.jpg)