Kairos is following an iterative approach for the development of its Fluoride Salt-Cooled High-Temperature Reactor (KP-FHR) technology. Its first Engineering Test Unit (ETU 1.0) is a full-scale, electrically heated prototype of the Hermes reactor which carried out more than 2000 hours of pumped salt operations demonstrating the design and integration of key systems, as well as exercising the supply chain and establishing new capabilities, including the production of the high-purity fluoride-lithium-beryllium (FLiBe) salt coolant.

The non-power Engineering Test Unit 2 (ETU 2.0) followed ETU 1.0 and will demonstrate modular construction methods: as part of the project the company is ramping up output of ASME U-stamped pressure vessels, producing specialised reactor components, and gaining proficiency in modular construction methods. Kairos Power has established a dedicated shop in its Albuquerque facility for KP-FHR vessel production.

(Image: Kairos Power)

Kairos has now announced the installation of the 14-foot-tall (4.3 metres) reactor vessel of its third Engineering Test Unit (ETU 3.0). The non-nuclear mockup is being built adjacent to the site of Hermes - a low-power reactor currently under construction to advance the company's commercial KP-FHR reactor.

The ETU 3.0 reactor vessel was fabricated in partnership with Cambridge Vacuum Engineering and the University of Sheffield's Advanced Manufacturing Research Centre, using cutting-edge electron beam welding technology. The ETU 3.0 vessel project allowed Kairos to evaluate the advanced welding technique to enable faster, more cost-effective production of reactor vessels with precise tolerances for future commercial deployments.

(Image: Kairos Power)

The KP-FHR is one of five technologies selected in 2020 to receive federal funding for risk reduction projects under the US Department of Energy's (DOE's) Advanced Reactor Demonstration Program (ARDP), with the department investing up to USD303 million in the Hermes reactor project. Under its agreement with the DOE, Kairos receives fixed, performance-based payments from DOE upon demonstrating the completion of pre-determined project milestones.

"Kairos Power's novel contract with DOE allows us to remain agile while demonstrating continued progress as a responsible steward of public funding," said Kairos Power CEO and co-founder Mike Laufer. "ARDP support is helping us to move quickly through progressively sophisticated iterations, gaining essential learning that will enable commercial deployment of our advanced reactor technology on a meaningful timeline."

(Image: Kairos Power)

The ETU 3.0 building is being constructed around the reactor vessel in a streamlined sequence, which allowed the oversized component to be moved into position before the roof and other elements are in place. Kairos is collaborating with Barnard Construction to build the facility, using it as a proving ground to refine civil construction methods and quality assurance procedures for the Hermes reactor.

In addition to piloting new construction methods and manufacturing processes, ETU 3.0 will ultimately support the Hermes reactor as an operator training centre and test platform for remote handling and maintenance equipment. The facility will help improve operator safety and reduce downtime by prequalifying procedures for maintaining and replacing high-temperature reactor systems and components.

Hermes is the first non-light-water reactor to be permitted in the USA in more than 50 years. It will not produce electricity, but Hermes 2 - a two 35 MWt-unit plant for which the US Nuclear Regulatory Commission issued a construction permit in November - will include a power generation system.

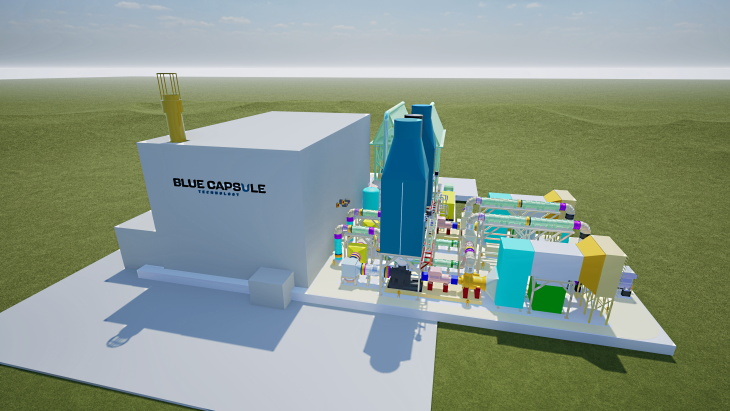

The ETU 3.0 building will also house a Modular Systems Facility where plant equipment modules for ETU 3.0 and the Hermes reactor will be staged, assembled, and tested prior to installation. Kairos said the modular reactor construction methods being piloted with the ETU series and Hermes will be foundational to reducing construction costs and timelines for future plant deployments.

"The ability to test innovative production methods with our non-nuclear iterations is a game-changer for us," said Kairos Power Vice President of Manufacturing Craig Gerardi. "By serving as a vehicle to exercise the supply chain and gain construction proficiency, the ETU programme helps build confidence in our ability to deliver reactors for Kairos Power customers."

The commercial version of the KP-FHR is expected to be deployed in the 2030s.

_15696.jpeg)

_87299.jpg)

_52351.jpg)