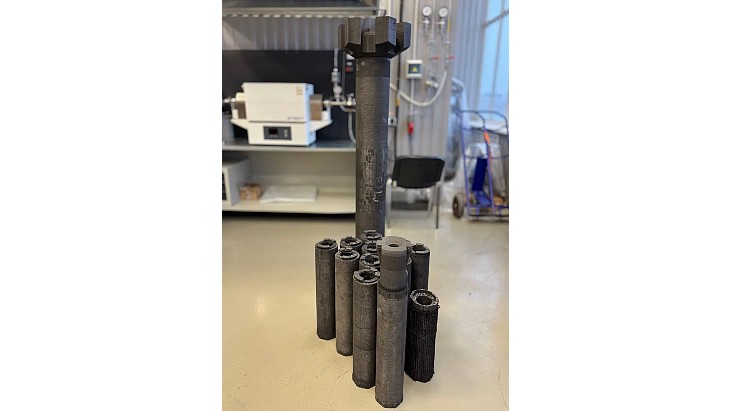

Russia's state nuclear corporation said its experts "created full-size models of individual structural elements, including a 1650 mm high support element (a set of which serves as a support for the active zone made of graphite fuel assemblies) and the working element of the control and protection system (a long flexible structure assembled from individual sections, each 500 mm high)".

Fyodor Grigoryev, the project's supervisor at Rosenergoatom, said the development of the HTGR reactor component manufacturing technology "will allow us to further apply the experience gained not only to the manufacture of other HTGR reactor components, but also to utilise the technology in other innovative projects in the Russian nuclear industry".

The development of a technology for creating structural elements for the HTGR from a carbon composite is described as the next significant stage in the implementation of the project to create a power plant with a HTGR and a chemical process section.

The HTGR project is aimed at a future nuclear power plant "as part of an investment project to create domestic technologies for large-scale production and consumption of hydrogen and hydrogen-containing products". The nuclear power plant will combine the HTGR reactor with chemical process equipment allowing "large-scale hydrogen production through steam-oxygen methane reforming without carbon dioxide emissions".

According to Rosatom the HTGR reactor plant, with a thermal capacity of 200 MW, "is designed to generate high-grade heat in the reactor core (the helium coolant temperature at the reactor core outlet is 850 degrees Celsius) to generate superheated steam (steam temperature 750 degrees Celsius) and transfer it to industrial consumers".

In December Rosatom said that tests had been successfully completed on fuel samples for high-temperature gas-cooled reactors under extreme conditions. Before the reactor tests the high-temperature gas-cooled reactor fuel - graphite cylinders with uniformly distributed spherical microfuel elements - was irradiated in research reactors under standard conditions for this type of fuel - at temperatures between 1,000 degrees Celsius and 1,200 degrees Celsius to various burnup levels.

Hydrogen is increasingly seen as a key component of future energy systems if it can be made without carbon dioxide emissions. Among its uses, it can help decarbonise heavy industries such as steelmaking and chemical industries as part of efforts to achieve carbon neutrality by 2050. According to World Nuclear Association information energy demand for hydrogen production could in the future exceed that for electricity production today.

_13505.jpg)

_87975.jpg)

_67826.jpg)

_87695.jpg)