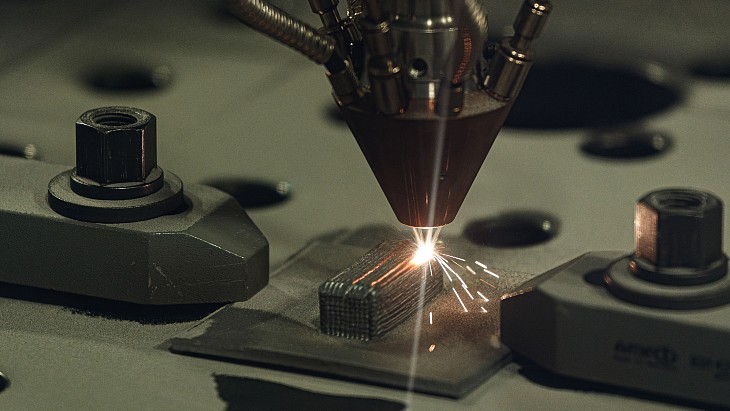

The first item produced in this way by the Afrikantov Experimental Design Bureau of Mechanical Engineering, part of Russia's state nuclear corporation Rosatom, is a terminal box.

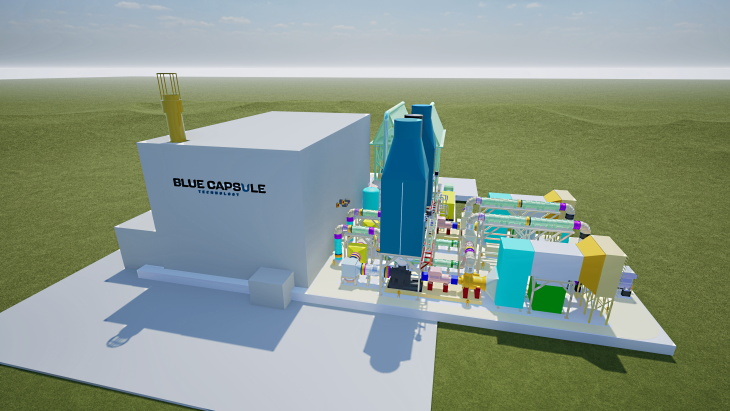

The RITM-200 reactors are used on Russia's newest range of nuclear icebreakers and are also the basis of the country's planned fleet of floating and land-based SMR plants.

Rosatom said the prototypes underwent a full range of tests before their feasibility was confirmed and "regulatory documentation has now been developed and approved, and the first Russian certificate from the Russian Maritime Register of Shipping has been received".

It added: "This project has enabled us to gain experience in manufacturing reactor equipment components using additive technologies, develop regulatory documentation in this area, and further develop the ability to manufacture more complex and critical components for the RITM-200 using a 3D printer."

Yuri Vytnov, Chief Technologist at Afrikantov OKBM, said: "Obtaining regulatory documentation for the first product for the RITM-200 reactor plant, manufactured using additive technologies, allows for the future replication of 3D printing technology to create various equipment for ship nuclear power plants, as well as other types and purposes of nuclear industry equipment."

Ilya Kavelashvili, Director of the Additive Technologies Business Unit at Rosatom's Fuel Division, said: "The use of 3D printing opens up new possibilities for design and production. Parts with optimised geometry and improved characteristics can be created. This allows for increased efficiency and reliability of the equipment, as well as a reduction in weight and cost."

Additive technologies - such as 3D printing where objects are "printed" by building up material layer by layer - allow the production of parts and components that are difficult to manufacture using traditional methods using casting and mechanical processing. In addition, 3D printing allows you to reduce the weight of products, optimise the materials used and reduce production times, It has been used in the past in Russia for test equipment and process tooling but this is the first time it has been used for reactor components.

The International Atomic Energy Agency sees considerable potential for 3D printing of parts in the nuclear energy sector, with the first use case being a 3D-printed impeller installed at a Slovenian reactor in 2017, while Oak Ridge National Laboratory printed brackets called channel fasteners which were installed in a nuclear power reactor in 2021, and Framatome installed the first 3D-printed stainless steel fuel component at the Forsmark nuclear power plant in Sweden in 2022. As well as Russia, other countries including South Korea and the UK are also using 3D printing to manufacture items.