Aseismic bearings are installed beneath the plant's nuclear island to decouple the reactor building from ground motion during an earthquake. By absorbing and dissipating seismic energy, they reduce the forces transmitted to the superstructure, preserving both integrity and functionality.

The project will be delivered from Skanska's fabrications facility in Doncaster, England, and includes building a prototype of the aseismic bearing pedestal. Skanska - one of Sweden’s largest companies - is one of the world's leading project development and construction companies.

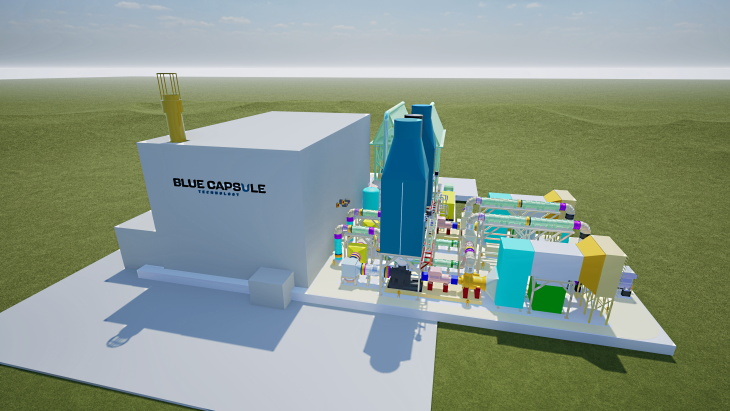

_e98d12e9.jpg)

(Image: Rolls-Royce SMR)

"Working with Skanska is a significant step forward in proving the capability of our aseismic bearing technology and demonstrating our modular approach to construction," said Ruth Todd, Rolls-Royce SMR Operations and Supply Chain Director. "By working with a trusted delivery partner, we are de-risking our 'fleet-based' approach and creating opportunities for more British and Czech suppliers to play a key role the Rolls-Royce SMR mission."

Adam McDonald, Executive Vice President at Skanska UK, added: "We'll be bringing our civil engineering, design and fabrications expertise to build and test a first-of-its-kind pre-cast bearing pedestal – a critical component for Rolls-Royce SMR in building new nuclear power generation. Over the coming months, we'll develop the prototype and run various technical trials at our Bentley Works facility in Doncaster. We are looking forward to playing our part in developing the next generation of nuclear energy."

The Rolls-Royce SMR is a 470 MWe design based on a small pressurised water reactor. It will provide consistent baseload generation for at least 60 years. Ninety percent of the SMR - measuring about 16 metres by 4 metres - will be built in factory conditions, limiting activity on-site primarily to assembly of pre-fabricated, pre-tested, modules which significantly reduces project risk and has the potential to drastically shorten build schedules.

It has been selected by both the Czech Republic and the UK governments for their respective proposed SMR programmes.

"The standardised bearing design is pre-qualified against a wide spectrum of seismic profiles, meaning the Rolls-Royce SMR can be sited nearly anywhere in the world without bespoke redesign," Rolls-Royce SMR said. "Proven in nuclear and civil applications, the aseismic bearing system aligns with international seismic codes and best practice guidelines, streamlining regulatory review and boosting stakeholder trust.

"This approach enables a flexible yet standardised SMR solution: a globally deployable plant design that adapts to local environments without compromising safety, performance, or efficiency."

_87299.jpg)

_52351.jpg)