The First Generation Magnox Storage Pond (FGMSP) was constructed in the 1950s to store, cool and prepare used Magnox nuclear fuel for recycling into new fuel.

During the FGMSP's 26-year operating lifetime it processed approximately 27,000 tonnes of fuel - almost 2.5 million fuel rods. Used nuclear fuel from the UK's nine Magnox stations, along with Magnox fuel from both Italy and Japan was held in the FGMSP. The pond holds some 14,000 cubic metres of contaminated water, in which is stored Magnox used nuclear fuel, radioactive sludge, miscellaneous nuclear wastes and skips. The plan is to progressively retrieve and treat the radiological inventory residing in the facility, reducing the on-going risk posed by its storage and then reducing the inherent hazard posed by the materials.

Zeolites were placed into the pond in the 1970s and 80s to help absorb radiation and make the facility safer for personnel. They now need to be removed as part of the pond clean-up programme. The zeolite skips account for one-quarter of the total number of skips in the pond.

In the process of removing the first Zeolite skip, the teams involved have recorded two other "landmark successes", Sellafield Ltd noted. "They're the first to put a nuclear waste product into a new British-made storage container, known as a self-shielded box. And the first to consign a self-shielded box to Sellafield's new Interim Storage Facility."

.jpg)

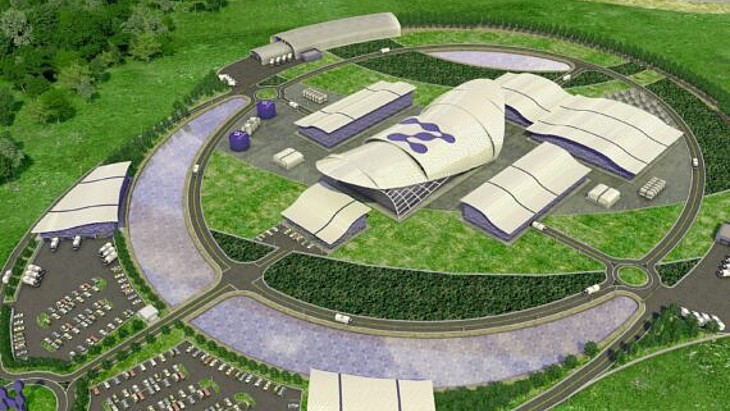

The FGMSP (Image: Sellafield Ltd)

"This is a fantastic achievement and a real step forward for us," said Carl Carruthers, head of legacy ponds for Sellafield Ltd. "Removing zeolite skips from the pond and transferring them to safer storage reduces risk and hazard on the site. It also frees up space in the pond which makes our sludge removal and clean-up work easier. The 29-tonne self-shielded boxes are built in the UK by Goodwin International via a contract with Westinghouse."

David Redpath, NDA group performance assurance director, added: "This accomplishment is not only a first for Sellafield, but a world's first for the nuclear industry. It is a true testament to the hard work and commitment of all those involved. The implementation of this new capability is a key step in reducing the hazard posed by the legacy ponds and demonstrates the strong collaboration between Sellafield and its supply chain."

Once waste is placed inside the self-shielded boxes, it is checked regularly using remote cameras in the box lid. Eventually, the zeolites will be removed from the boxes and encapsulated, ready for consignment to the UK's Geological Disposal Facility.

.jpg)

_55401.png)

_23009.jpg)