Igor Kotov, general director of Atomenergomash, said the Akkuyu construction project "is under close scrutiny at the highest state level" by both the Turkish authorities and the Russian government, whose state nuclear company Rosatom is responsible for building the plant. "This imposes a special responsibility" on Atomenergomash, which is a subsidiary of Rosatom. As the component was completed on 18 October, he said that "optimal solutions" had been found between the partners.

The bottom head of the reactor pressure vessel was completed in two stages. On 24 September, a seamless flat billet weighing 80 tons was made from a cylindrical section of metal. On 18 October, that billet was heated for 6 hours to a maximum temperature of 1020°C and moved to a 10,000 ton press to be formed into its final shape. The metal is 300 mm thick.

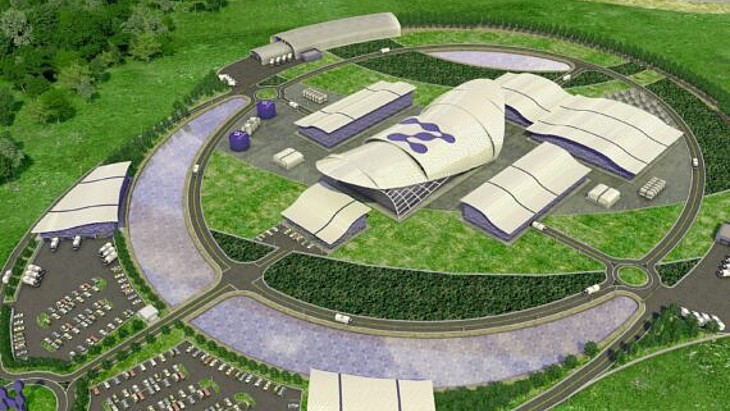

The part will next be welded to the bottom of the 12 metre long cylindrical reactor pressure vessel, which in total will weigh 330 tons. When finished it will be transported 3000 kilometres to Akkuyu on Turkey's Mediterranean coast for installation at the third nuclear power unit there, which is about to start construction.

.jpg)

_55401.png)

_23009.jpg)