The plant is expected to be the first facility in the USA to exclusively manufacture fuel for advanced small modular reactors (SMRs) and will fabricate X-energy’s proprietary tristructural-isotropic (TRISO) fuel for the first proposed deployment of the Xe-100 in partnership with Dow, Inc at Dow's Seadrift site on the Texas Gulf Coast, and future Xe-100 deployments.

Deployment of the Xe-100 high-temperature gas-cooled modular reactor is receiving support through the US Department of Energy’s (DOE) Advanced Reactor Demonstration Program (ARDP). The programme is providing up to 50% cost-shared funding for the Xe-100 Advanced Reactor Demonstration Project, including construction of the TX-1 fuel fabrication facility

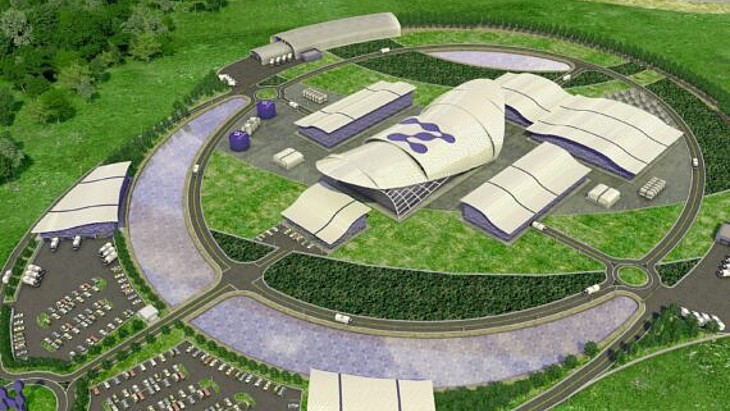

In August, TRISO-X announced that it had selected Clark Construction Group for a USD48.2 million award to complete the building construction phase of TX-1, including the completion of the core and shell of the 214,812 square foot (19,957 square metres) facility. At the same time, the company said it had received DOE approval to authorise an additional USD30 million for early procurement of critical long-lead equipment and materials to support the successful delivery of subsequent construction phases, and to help keep the project on schedule.

TX-1 is the first of two planned TRISO manufacturing facilities at X-energy's site in Oak Ridge, and is set to be the first Category II Fuel Fabrication Facility licensed by the US Nuclear Regulatory Commission (NRC) in the USA with an estimated output of 5 tonnes of uranium or 700,000 TRISO pebbles per year, enough fuel for up to 11 Xe-100 reactors.

Pebbles of TRISO-X fuel recently began 13 months of irradiation testing at Idaho National Laboratory to evaluate fuel performance across operating scenarios and qualify them for commercial use.

The NRC groups what it calls special nuclear materials - plutonium, uranium-233, or uranium enriched in the isotopes uranium-233 or uranium-235 - and the facilities that possess them into three categories based upon the materials' potential for use in nuclear weapons or their strategic significance. The NRC’s physical security and safeguards requirements reflect these categories. Category II materials are classed as having moderate strategic significance, while Category I materials are classed as having high strategic significance and Category III as having the lowest significance.

Currently, three US fuel fabrication plants processing low-enriched uranium are licensed as Category III facilities by the NRC. Two fabrication plants are licensed as Category I facilities and can produce nuclear fuel containing high-enriched uranium - for example, under government contracts to produce fuel for the US Naval Reactors programme - as well as low-enriched uranium. The high-assay low-enriched uranium - or HALEU - that will be needed to fuel many of the SMRs currently under development will need to be fabricated in Category II-licensed facilities. The NRC has received applications for several proposed plants from different companies.

"The start of vertical construction marks another significant milestone in bringing our bold vision for the future of nuclear energy to life," TRISO-X President Joel Duling said. "As TX-1 takes shape, it will stand as a symbol of our team's relentless dedication and determination to bring this transformative project forward in just a few years, not decades."

_50545.jpg)

_55401.png)

_23009.jpg)