The seventh roofing truss, weighing 52 tonnes and with a span of 42 metres, was moved into position using a Liebherr crane during a two-and-a-half-hour process at the site at the Siberian Chemical Combine complex in Seversk in Russia.

(Image: Rosatom)

The first six trusses have been put into position in a process which began in May.

Ivan Babich, director of the BREST-OD-300 power unit at the complex, said: "Completion of the roofing work and the creation of a thermal circuit for the machine room will allow us to continue installing the turbine room equipment and begin assembling the power unit's turbo unit during the winter."

Meanwhile, the metal shell of the reactor's central cavity, which weighs 143 tonnes and is more than 14 metres tall with a diameter of 8 metres, was installed in its design position (see picture below). That followed a two-month journey involving travel by river, sea and by road.

(Image: Rosatom)

The BREST-OD-300 reactor has an integral layout - its vessel is not an all-metal structure, instead it is a metal-concrete structure with the space between the cavities gradually filled with concrete during construction. Because of its large size, it can only be delivered in parts, with assembly only possible at the construction site.

(Image: Rosatom)

Babich said: "After installing the central cavity shell, we plan to begin installing the four shells of the peripheral cavity, which will house the steam generators and circulation pumps. Together, all the metal shells form a lead coolant circulation loop. The space between the cavities will be gradually filled with a special heat-resistant concrete, which provides radiation and thermal protection and ensures the structural strength of the primary coolant circuit boundary."

Road signs and power lines had to be moved during its journey to the site (Image: Rosatom)

The background

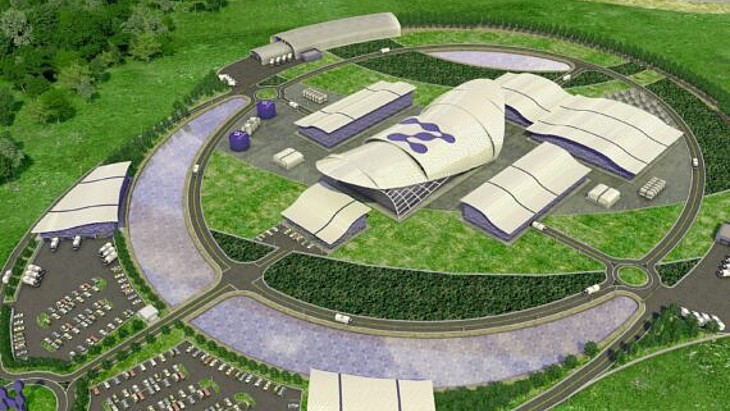

The BREST-OD-300 fast reactor is part of Rosatom's Proryv, or Breakthrough, project to enable a closed nuclear fuel cycle. The 300 MWe unit will be the main facility of the Pilot Demonstration Energy Complex at the Siberian Chemical Combine site. The complex will demonstrate an on-site closed nuclear fuel cycle with a facility for the fabrication/re-fabrication of mixed uranium-plutonium nitride nuclear fuel, as well as a used fuel reprocessing facility.

A progress update in November said that the cooling tower had been built, the walls of the reactor containment building erected and the reactor shaft and the enclosing structure of the reactor vessel have also been installed.

Initial operation of the demonstration unit will be focused on performance and after 10 years or so it will be commercially oriented. The plan has been that if it is successful as a 300 MWe (700 MWt) unit, a 1200 MWe (2800 MWt) version will follow - the BR-1200.

_55401.png)

_23009.jpg)