NuScale says that one of its scalable plants featuring 12 of its power modules could provide desalinated water to a city of 2.3 million while also providing electricity to 400,000 homes.

The US-based company partnered with the US Department of Energy’s Pacific Northwest National Laboratory "to examine hydrogen production from an inert salt drawn from water desalination byproducts that is safe and easy to transport. NuScale’s hydro-thermal chemical decomposition approach to hydrogen production does not require electrolysis of water, driving down energy and water usage while lowering costs. Moreover, it is carbon-free if the energy for the conversion processes comes from NuScale’s integrated energy systems".

NuScale says its novel approach can tackle both the issue of brine waste from the desalination process and carbon emissions from hydrogen production.

José Reyes, co-founder and chief technology officer at NuScale, said: "The near-term predictions of global water scarcity have become increasingly alarming while the interest and financial incentives for producing clean hydrogen continue to grow. We believe our breakthrough innovation can meet our global water challenges while providing clean, carbon-free energy."

NuScale has an Integrated Energy System simulator for hydrogen production, storage and power production at its Oregon headquarters. It uses it as it seeks to "dynamically evaluate and optimise different configurations for a wide range of commercial-scale industrial applications requiring greater than 200 metric tonnes of hydrogen per day".

Background

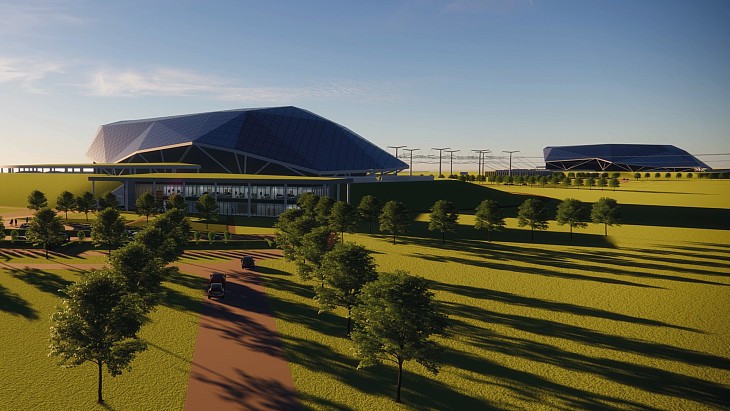

Last month the US Nuclear Regulatory Commission (NRC) approved the 77 MWe version of the NuScale Power Module. The NRC accepted NuScale's previous design certification application for a plant comprising up to twelve 50 MWe power modules in March 2017. The regulator certified the 50 MWe version design in January 2023, which made it the first SMR design to be cleared by the regulator for use in the USA.

A standard design approval indicates that a proposed reactor design meets applicable NRC safety requirements. Companies that seek to use the design would have to file applications seeking permission to construct and operate a nuclear reactor using the approved design.

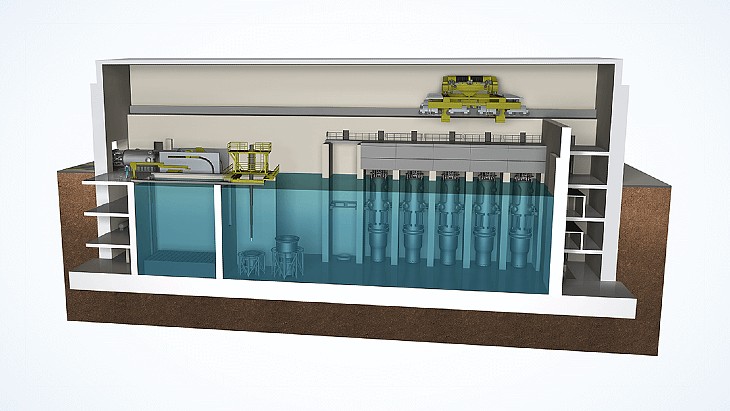

NuScale says its power module will have a 36 month construction period, weigh 700 tonnes in total and be shipped from a factory in three segments via road, rail or barge and operate using standard light water reactor fuel with a 21 month refuelling cycle with fuel enriched up to 5%.

Hydrogen is increasingly seen as a key component of future energy systems - in industrial processes and for transportation - if it can be made without carbon dioxide emissions. World Nuclear Association's Information Paper on hydrogen says: "Nuclear energy can be used to make hydrogen electrolytically, and in the future high-temperature reactors are likely to be used to make it thermochemically. The energy demand for hydrogen production could exceed that for electricity production today."

_19544_40999.jpg)

_66668.jpg)